CLIPFIX – HIDDEN SCREW STANDARD FIXING

Using the Clipfix standard system will leave approximately a 6-8mm gap between boards.

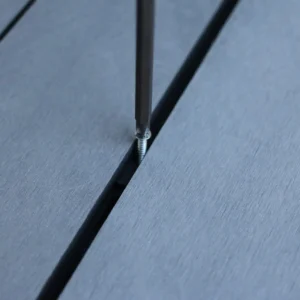

- Insert the Clipfix clip into the groove as shown. Screw down approximately 4 mm to hold the clip in place.

- Get your next board and push into place.

- Repeat these steps and lay approximately five boards. Ensure your boards are square, adjust as necessary.

- Screw down the aligned decking. Do not overtighten, use a low medium torque setting on your drill.

- Repeat steps 1 – 4 until you have completed your project.